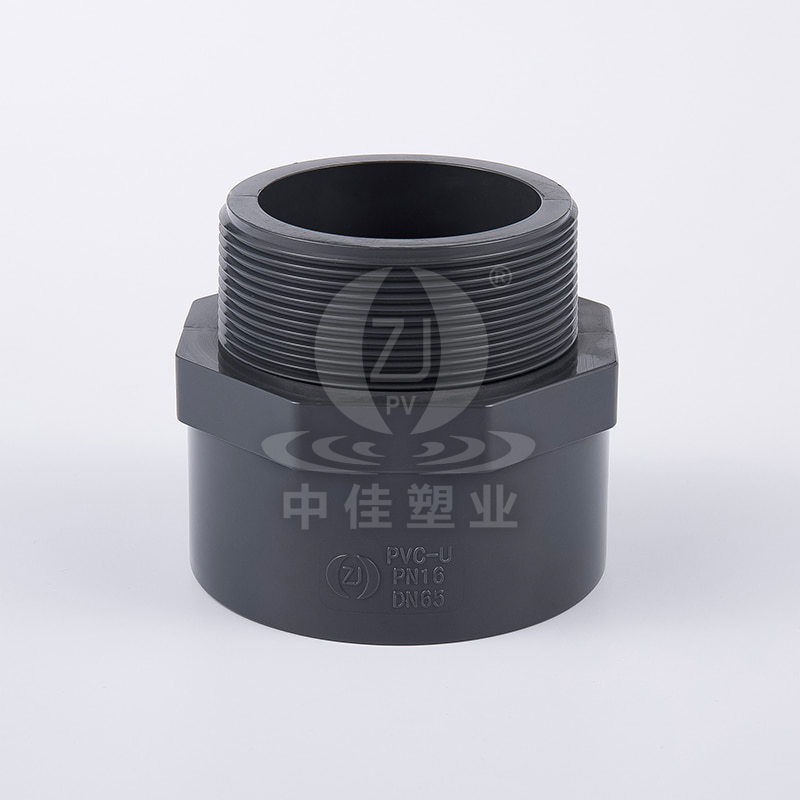

PVC-U male adapters are essential components in industrial chemical piping systems, connecting pipes and equipment while providing resistance to corrosion and chemical damage. These adapters are commonly used in industries handling acids, alkalis, and other corrosive chemicals due to their durability, lightweight design, and ease of installation. Selecting the correct adapter is critical to ensure system safety, efficiency, and long-term reliability.

This article provides a comprehensive guide to choosing the right PVC-U male adapter for industrial chemical applications, focusing on material properties, sizing, compatibility, pressure ratings, and installation practices.

PVC-U, or unplasticized polyvinyl chloride, is a highly rigid and chemically resistant material suitable for industrial applications. Key properties to consider when selecting adapters include:

Selecting the right adapter requires careful assessment of several factors that affect compatibility, performance, and safety.

Accurate sizing is essential for leak-free connections. Measure both the pipe outer diameter and the equipment inlet size. PVC-U male adapters are available in a range of diameters, typically matching standard pipe sizes. Ensure a snug fit without excessive force to prevent cracking or deformation.

Industrial systems often operate under varying pressures. Select a PVC-U male adapter with a pressure rating suitable for your system, considering both operating and surge pressures. Exceeding the pressure limit can cause failure and leaks, risking chemical exposure and equipment damage.

Ensure the adapter material is compatible with the chemicals being handled. While PVC-U is highly resistant, some strong solvents or chlorinated compounds may require alternative materials such as CPVC or PVDF. Always check chemical compatibility charts provided by manufacturers.

PVC-U male adapters typically feature either solvent-weld or threaded connections. Choose the type based on:

Consider the environment and operational conditions when selecting adapters:

Selecting adapters that meet recognized standards ensures reliability and safety. Look for certifications such as:

Proper installation maximizes adapter performance and longevity:

Routine maintenance ensures the long-term efficiency of PVC-U adapters:

| Factor | Recommendation |

| Pipe Size | Match exact OD/ID |

| Connection Type | Threaded or Solvent-Weld |

| Chemical Compatibility | Check manufacturer charts |

| Pressure Rating | ≥ system operating pressure |

| Temperature Limit | ≤ 60°C for PVC-U |

Selecting the right PVC-U male adapter for industrial chemical applications requires careful consideration of material properties, pipe and equipment sizing, pressure rating, chemical compatibility, and installation practices. Following proper installation and maintenance procedures ensures system reliability, safety, and long-term performance. By adhering to these guidelines, engineers and maintenance teams can maximize efficiency and prevent costly leaks or failures in chemical piping systems.