In modern piping systems, tee fittings play an essential role in branch connections for transporting water, gas, chemicals, or other fluids. Among the many types of materials used to make tee fittings, HDPE (High-Density Polyethylene) and PVC-U (Unplasticized Polyvinyl Chloride) are two of the most commonly used plastics. Though both are widely adopted in plumbing and industrial systems, they differ in material characteristics, performance, and applications.

1. Material Composition

HDPE Tee is made from high-density polyethylene, a flexible thermoplastic known for its toughness, corrosion resistance, and weldability.

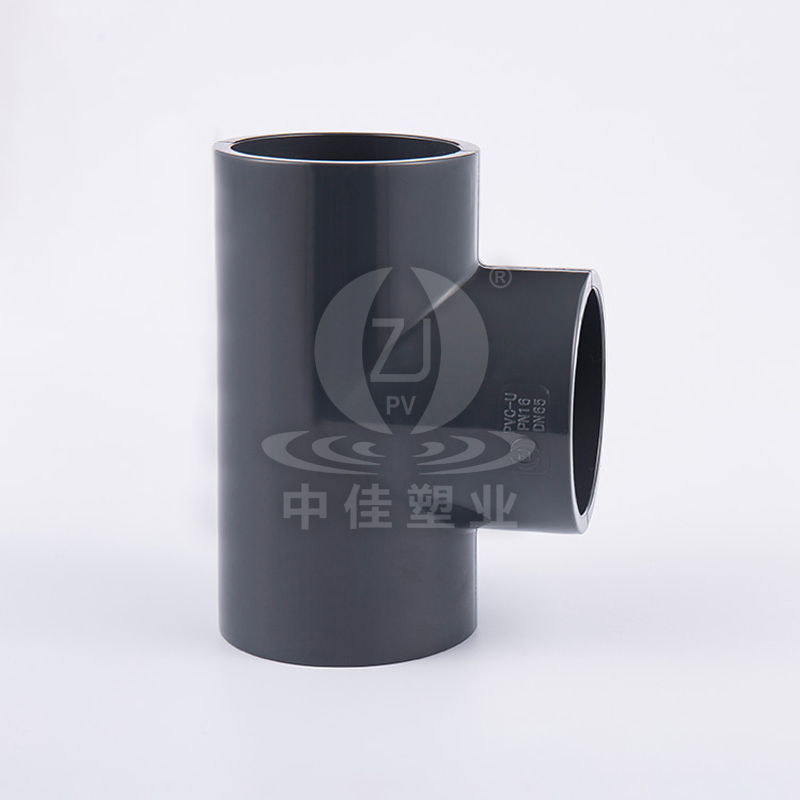

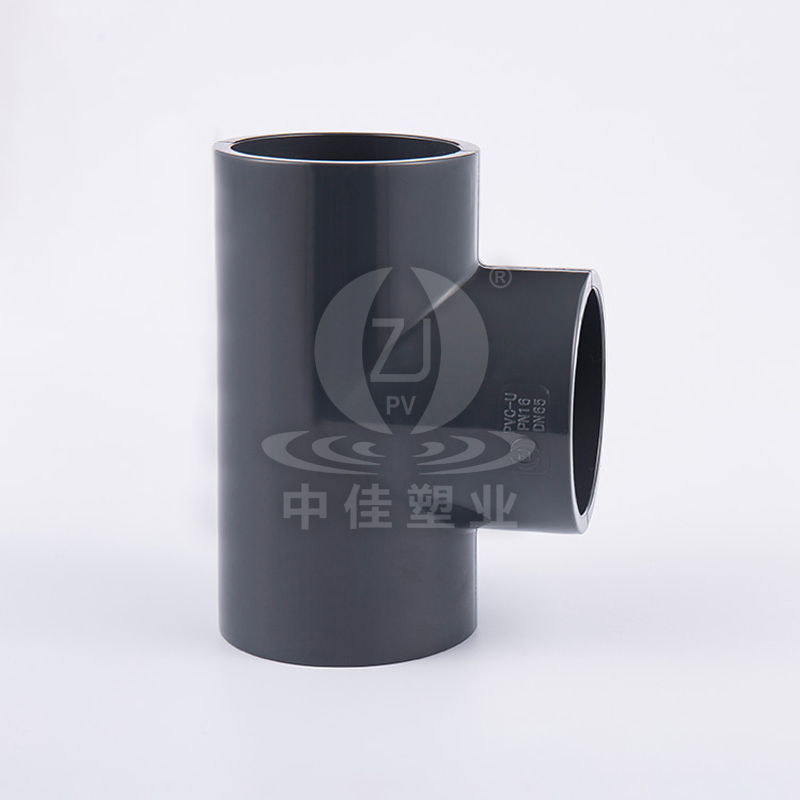

PVC-U Tee is made from unplasticized polyvinyl chloride, a rigid plastic with good mechanical strength and chemical resistance but less flexibility.

The basic difference lies in rigidity versus flexibility — PVC-U is stiffer, while HDPE is more ductile.

2. Mechanical and Thermal Performance

| Feature | HDPE Tee | PVC-U Tee |

|---|---|---|

| Flexibility | High (resists deformation) | Low (can crack under stress) |

| Impact Resistance | Excellent (especially in cold weather) | Moderate (brittle in low temperature) |

| Temperature Range | -40°C to 60°C | 0°C to 45°C |

| Connection Method | Heat fusion (strong and leak-proof) | Solvent cement or rubber ring seal |

| Chemical Resistance | Excellent | Very good, but sensitive to strong solvents |

| Pressure Rating | Typically higher | Moderate |

HDPE tees offer better impact resistance and temperature tolerance, especially in outdoor and underground installations. PVC-U tees, however, are easier to install using glue or gasket seals and are ideal for systems that operate under moderate conditions.

3. Application Scenarios

HDPE Tees are widely used in:

Municipal water supply and drainage

Agricultural irrigation

Gas distribution networks

Mining and industrial fluid transport

Underground piping in difficult terrain

Their high durability and resistance to ground movement make them ideal for demanding environments.

PVC-U Tees are commonly used in:

Residential and commercial drainage

Rainwater and wastewater systems

Electrical conduit networks

Low-pressure cold water pipelines

PVC-U tees are more suitable for indoor or low-pressure applications where ease of installation and cost are important factors.

4. Installation and Cost Considerations

HDPE tees require specialized welding equipment for heat fusion, which ensures a permanent, leak-free connection. However, this adds labor and equipment costs.

PVC-U tees can be installed quickly with solvent cement or rubber gaskets, making them more convenient for small-scale or DIY installations. In general, PVC-U fittings are more cost-effective upfront, while HDPE offers longer-term reliability.

Both HDPE and PVC-U tees serve critical roles in piping systems but are suited to different applications. HDPE tees are the better choice for high-performance, outdoor, or industrial environments requiring strength and flexibility. PVC-U tees are ideal for cost-sensitive projects where ease of installation and rigidity are more important.