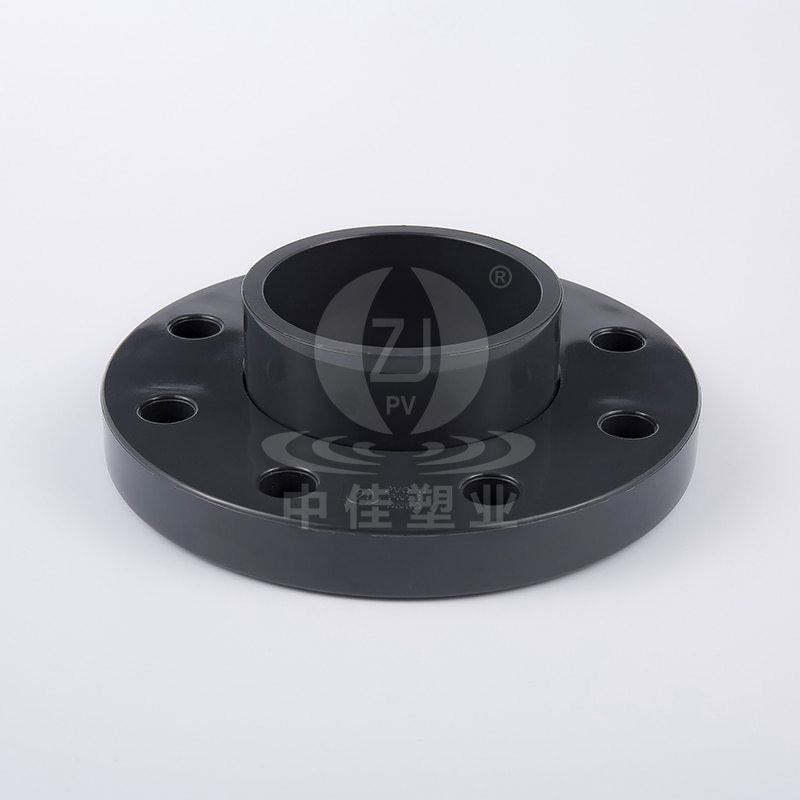

In modern plastic pipe connection systems, PVC-U Van Stone Flange is a common connection accessory. It is widely used in water supply and drainage, chemical processing, aquaculture and other fields due to its advantages such as detachable, flexible installation and low cost.

1. What is PVC-U Van Stone Flange?

PVC-U is the abbreviation of unplasticized polyvinyl chloride, which is a hard plastic material commonly used in water supply pipes. Van Stone Flange consists of two parts:

Flange Ring: Generally PVC-U injection molding, used for connection with bolts;

Stub End / Hub: Connected to the pipe port by hot melt or glue, it plays a sealing and pressure-bearing role.

The main advantage of the slip-on flange is that the flange ring can rotate freely, which makes it easier to align with the screw hole during installation, and is convenient for connection and disassembly. It is especially suitable for systems that require frequent maintenance or replacement of parts.

2. Performance characteristics of PVC-U materials

Strong corrosion resistance: It can be in contact with weak acid, weak alkali and various inorganic salt solutions for a long time, and is suitable for most clean water or industrial water.

Light weight and easy installation: It is about 50% lighter than metal flanges, reducing labor costs;

Stable hot melt or adhesive connection: The back seat part is firmly connected and not easy to leak;

Economical price: It is suitable for large-scale use and reduces the project budget.

However, it also has the characteristics of low temperature resistance (<60℃) and general impact resistance, so it is necessary to combine the actual pressure and environment to determine whether it is suitable for high-pressure systems.

3. Applicable conditions and suggestions in high-pressure water systems

In order to ensure the safe operation of PVC-U slip-on flanges in high-pressure systems, it is recommended to pay attention to the following points:

Confirm whether the pressure level (PN) mark meets the design requirements;

The flange and the pipe match tightly, and components of different pressure levels cannot be mixed;

Reasonably select the material of the sealing gasket (such as EPDM, NBR, etc.) to improve the sealing performance;

Avoid the system temperature exceeding 45~50℃ to prevent the material from softening and deforming;

The pipe fixing support is sufficient to prevent the connection from loosening due to water hammer or vibration.

4. Comparison of alternative solutions

If the system working pressure is higher than 1.6 MPa for a long time, or the ambient temperature is high (such as factory hot water pipes), the following alternative materials can be considered:

CPVC (chlorinated polyvinyl chloride) flange: temperature resistance up to 90℃, stronger pressure resistance;

PP-H (polypropylene high crystallinity) flange: strong corrosion resistance, suitable for chemical media;

Stainless steel slip-on flange + PVC-U back seat combination: improve strength and sealing, taking into account economy and safety.

PVC-U slip-on flanges have excellent sealing and stability within normal temperature and medium pressure ranges, and can be fully applied to most medium and low pressure water supply systems (PN10 or PN16 grade). However, for continuous high pressure or high temperature environments, their applicability is limited, and they need to be carefully selected in combination with factors such as pressure, temperature and chemical media. Reasonable design and standardized installation will enable PVC-U flanges to play a greater role in water treatment, municipal water supply and environmental protection projects.