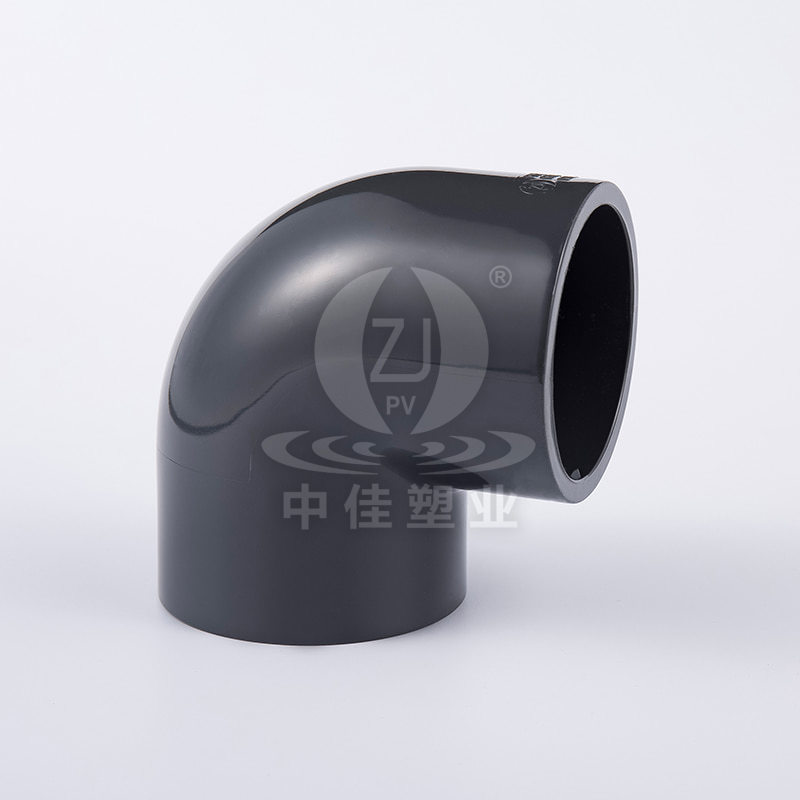

UPVC 90° elbows are essential components in piping systems, providing a right-angle turn to redirect flow without compromising system integrity. Their durability, corrosion resistance, and cost-effectiveness make them popular in residential, commercial, and industrial plumbing applications. Understanding key selection factors ensures optimal performance and longevity of the piping network.

The material quality of UPVC elbows significantly affects their performance. UPVC, or unplasticized polyvinyl chloride, offers high rigidity, chemical resistance, and low thermal expansion. Choosing the right grade and thickness ensures the elbow can withstand system pressure and environmental factors.

UPVC is inherently resistant to many chemicals and corrosion. However, it is essential to consider the specific substances transported through the piping system. For aggressive chemicals or high-temperature fluids, specialized UPVC grades may be necessary to prevent degradation.

Each UPVC elbow comes with specific pressure and temperature ratings. Selecting an elbow that exceeds the maximum system pressure and temperature ensures safety and longevity. Check manufacturer datasheets for maximum allowable pressure at different temperatures.

Correct sizing of the elbow is critical for maintaining proper flow rates and avoiding turbulence or pressure drop. Consider the internal diameter of the elbow and its compatibility with the rest of the piping system.

Ensure the UPVC 90° elbow matches the pipe’s nominal diameter and connection type. Mismatched dimensions can cause leaks or mechanical stress on the system.

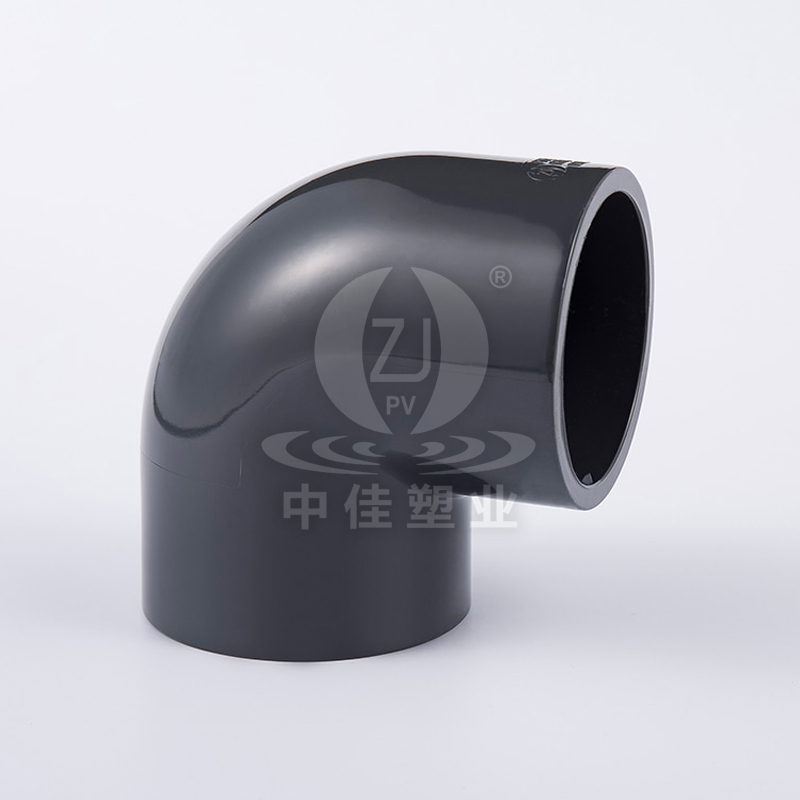

Wall thickness affects the strength and pressure handling of the elbow. Standard elbows come in different schedules, such as SCH 40 or SCH 80. Choose the wall thickness according to system pressure requirements.

UPVC elbows can be joined to pipes using solvent cement, mechanical couplings, or threaded connections. Understanding the connection method is essential for installation and maintenance.

Solvent welding chemically fuses the elbow to the pipe, creating a strong, leak-proof joint. Proper surface preparation and curing time are critical for effectiveness.

Mechanical couplings allow for easy installation and disassembly. They are suitable for systems that require maintenance or frequent reconfiguration.

Threaded UPVC elbows are used in smaller diameter systems, providing easy assembly without adhesives. Ensure proper thread sealing with Teflon tape or thread sealant.

The design of a 90° elbow affects fluid dynamics within the system. Abrupt changes in direction can cause pressure drops and turbulence, impacting efficiency.

Long radius elbows provide smoother flow with less turbulence, reducing wear on the system. Short radius elbows save space but can increase friction loss.

Consider the system’s flow rate and velocity when choosing an elbow. High-velocity systems benefit from long radius elbows to minimize energy losses and pressure drops.

Durable UPVC elbows reduce maintenance frequency and system downtime. Check for UV resistance if installed outdoors, and verify impact resistance for areas prone to mechanical stress.

UPVC can degrade under prolonged exposure to sunlight. Select elbows with UV stabilizers or provide protective coatings to extend lifespan.

The elbow should withstand mechanical stresses during installation and operation. Reinforced UPVC or thicker-walled elbows improve resistance to cracking and breakage.

Ensure that UPVC elbows comply with relevant industry standards, such as ASTM, ISO, or DIN. Certified products guarantee material quality, dimensional accuracy, and safe performance.

While cost should not compromise quality, consider the price in relation to durability and performance. Ensure the selected elbow is readily available for maintenance or system expansion.

Choosing the right UPVC 90° elbow requires careful consideration of material quality, size, connection methods, flow dynamics, durability, and standards compliance. Evaluating these factors ensures efficient, safe, and long-lasting piping systems, minimizing maintenance needs and optimizing performance.