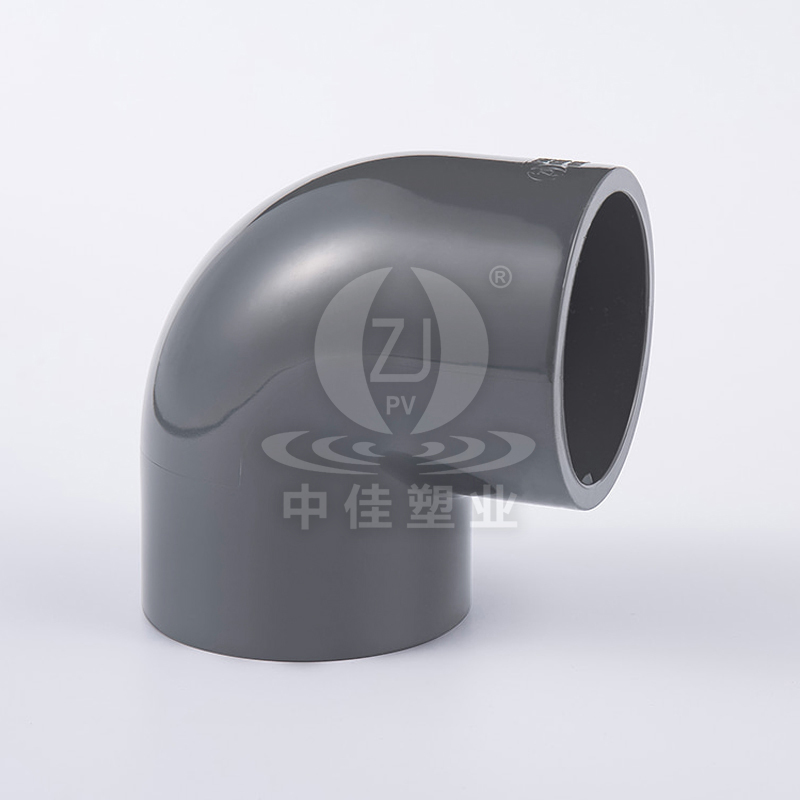

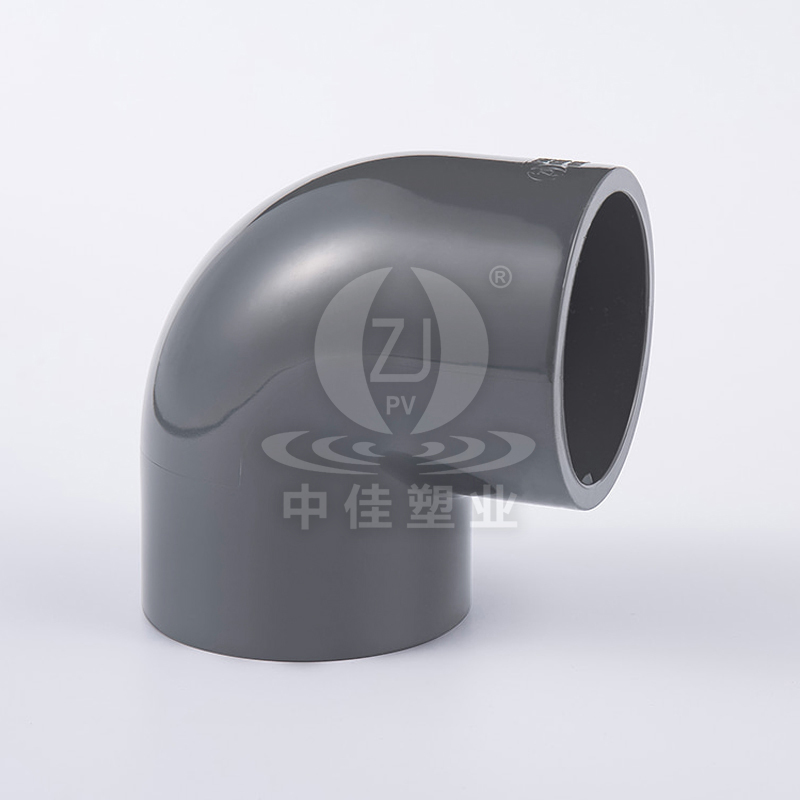

In various piping systems such as construction, chemical industry, water supply and drainage, the change of the direction of the pipeline needs to be achieved with the help of certain connectors, and PVC-C Elbow 90° is one of the indispensable pipe fittings. It not only helps to achieve flexible adjustment of the pipeline direction, but also shows superior performance in high temperature and high corrosion environment. So, what is PVC-C Elbow 90°? What are its characteristics, application scenarios and advantages?

1. What is PVC-C Elbow 90°?

PVC-C is the abbreviation of Chlorinated Polyvinyl Chloride. It is an engineering plastic that improves its thermal stability and chemical resistance through chlorination reaction on the basis of ordinary PVC. PVC-C Elbow 90° refers to a 90-degree pipe elbow connector made of this material, which is used to connect two sections of PVC-C pipes at right angles.

This type of pipe fitting is usually injection molded and is suitable for locations where the direction of the pipeline needs to be changed, especially corner pipe laying, such as wall corners, ground pipeline branches, etc.

2. What are the unique advantages of PVC-C materials?

PVC-C materials have more excellent properties than ordinary PVC and are suitable for more demanding use environments:

Higher heat resistance

The heat resistance temperature of ordinary PVC is only about 60°C, while PVC-C can withstand liquid transportation up to 90~100°C, suitable for hot water systems or high-temperature process pipelines.

Stronger chemical stability

It has excellent corrosion resistance to most acids, alkalis, salt solutions, and organic solvents, and is widely used in chemical transportation pipelines.

Better mechanical strength

Chlorination modification enhances the toughness and impact resistance of the material, making it less likely to break during transportation and installation.

Longer service life

It has strong anti-aging ability and can maintain a long life outdoors or under ultraviolet radiation.

3. What are the structures and classifications of PVC-C Elbow 90°?

According to different connection methods and usage requirements, PVC-C 90-degree elbows can be divided into the following types:

1. Socket Type

The most common form, which uses glue or hot melt to insert the connection, is suitable for most residential and light industrial applications.

2. Threaded Type

With internal or external threads, it is easy to disassemble and maintain, and is mostly used for temporary or frequently replaced pipe connections.

3. Flanged Type

Suitable for large-diameter, high-pressure or industrial-grade systems, it needs to be fixed with bolts, has reliable sealing and is easy to maintain.

4. With inspection port type

Some special elbows have inspection holes or observation ports for detecting and cleaning the inside of the pipe.

4. In which industries is PVC-C Elbow 90° widely used?

PVC-C elbows are widely used in the following fields due to their excellent corrosion resistance and temperature resistance:

1. Building water supply and drainage systems

Applicable to hot water pipes and air conditioning condensate pipe systems in residential and commercial buildings, replacing traditional metal pipes.

2. Industrial chemical pipelines

Such as chemical transportation, acid and alkali discharge, and water treatment systems, PVC-C elbows can withstand corrosive media for a long time.

3. Pharmaceutical and electronic industries

Used in clean workshops, high-purity water systems, and dust-free workshop pipelines to ensure that the system is not contaminated.

4. Swimming pools and SPA equipment

Can be used in high-temperature circulating water systems to avoid the risk of water leakage caused by thermal expansion and contraction.

5. Agriculture and greenhouse irrigation

Lightweight, weather-resistant, and UV-resistant, suitable for outdoor complex terrain pipe laying.

5. What is the installation method of PVC-C Elbow 90°?

When installing PVC-C 90° elbows, the following methods are usually used:

Glue bonding method (commonly used for socket type)

Use special PVC-C adhesive to insert and glue the pipe and elbow firmly, which is suitable for small-diameter pipeline systems.

Hot melt connection method

Heat the connection part to soften it and then quickly plug and cure it to form a strong seal.

Threaded connection method

After installing the sealing tape on the pipe or joint, rotate the connection for easy disassembly.

Flange connection method

Connect with gaskets and bolts, suitable for high pressure and large flow environments.

The following points should be noted during installation:

Keep the interface clean and dry;

Wait for curing time after glue bonding;

Avoid stress concentration of pipes under thermal expansion and contraction;

Avoid exposure to the sun and strong impact.

6. What are the sizes and standards of PVC-C Elbow 90°?

PVC-C elbows have a wide range of specifications, usually ranging from 20mm to 315mm. Common international standards include:

ASTM D1784 / D2466 / D2846 (American standard)

ISO 15877 (international standard)

DIN 8079 / 8080 (German standard)

JIS K6742 (Japanese standard)

The dimensions, tolerances and pressure levels of different standards are slightly different, so you should pay attention to matching when selecting.

7. What are the advantages of PVC-C Elbow 90°?

| Advantages | illustrate |

| Strong corrosion resistance | Can be used for conveying complex media such as acids, alkalis, organic solvents, etc. |

| Lightweight and easy to install | Compared with metal elbows, the weight is only 1/5, and the construction efficiency is high |

| Good sealing | There is basically no leakage risk after gluing or welding |

| Non-conductive | Prevent electrochemical corrosion, suitable for underground installation |

| Lower cost | Material and installation costs are lower than metal piping systems |

| Clean appearance | Smooth surface, not easy to scale, easy to clean |

8. FAQ of PVC-C Elbow 90°

Q1: Can PVC-C elbows be used in drinking water systems?

A: Yes. PVC-C material is non-toxic, odorless, and meets many international drinking water safety standards.

Q2: How high a temperature can a PVC-C elbow withstand?

A: Usually the highest temperature resistance can reach 95°C, and special modified products can reach 110°C.

Q3: Is it the same as CPVC elbow?

A: Yes, PVC-C is another name for CPVC (Chlorinated Polyvinyl Chloride). The names are slightly different, but the materials are the same.

Q4: Can PVC-C elbows be mixed with PVC pipes?

A: In some cases, it can, but it should be noted that the thermal expansion coefficients of the materials are different. Long-term use may cause stress concentration, seal aging and other problems.

Conclusion: PVC-C Elbow 90°, small parts carry big projects

Although PVC-C Elbow 90° is just a pipe fitting, it plays a vital role in connection and steering in complex piping systems. Its high temperature resistance, corrosion resistance, and easy installation make it one of the preferred components in various engineering systems.

With the widespread application of energy-saving, environmentally friendly and high-performance materials, PVC-C pipe fittings are gradually replacing traditional metal parts and becoming the "green skeleton" in modern fluid delivery systems. In the future, PVC-C Elbow 90° will continue to play its irreplaceable value in higher standards and smarter systems.