In modern building and industrial piping systems, UPVC pipe fittings (Unplasticized Polyvinyl Chloride Pipe Fittings) have become an indispensable and important material due to their excellent performance and broad application prospects. UPVC is an unplasticized polyvinyl chloride material with good corrosion resistance, mechanical strength and service life. It is widely used in water supply, drainage, sewage and chemical industries.

UPVC pipe fittings refer to various accessories used to connect UPVC pipe systems. Common types include:

Tee: used for branch connection of pipes;

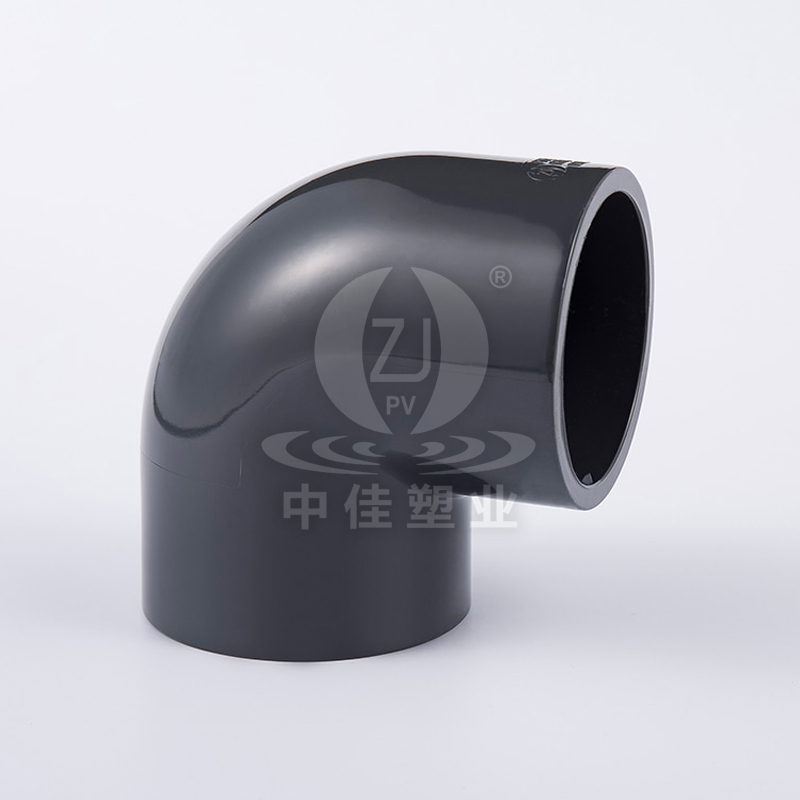

Elbow: to achieve pipe turning, common angles are 45° and 90°;

Reducing joint: connect pipes of different diameters;

Flange: detachable connection with other equipment or valves;

Pipe caps and pipe plugs: used for plugging the end of the pipe;

Straight joints (sleeves): used for straight connection of two sections of pipes with the same diameter.

These pipe fittings are usually manufactured by injection molding process, with the advantages of standard size, reliable connection and convenient installation.

Strong corrosion resistance: UPVC material has good corrosion resistance to various chemical substances such as acids, alkalis and salts, and is suitable for a variety of complex environments.

Non-conductive and high safety: It has unique advantages in places with high electrical insulation requirements, such as power engineering.

Lightweight and high strength: Compared with metal pipes, UPVC is lighter, easier to carry and construct, and has sufficient mechanical strength.

Good sealing: UPVC pipe fittings and pipes are often connected by socket-and-spigot adhesive, which can effectively prevent liquid leakage.

Long service life: Under normal use conditions, the life of UPVC pipe fittings can reach more than 50 years, with low maintenance costs.

Building water supply and drainage system: widely used in cold water pipes, wastewater discharge pipes, rainwater pipes and other systems in residential and commercial buildings;

Municipal engineering: used in the construction of urban underground drainage pipe networks, with good pressure resistance and weather resistance;

Agricultural irrigation: suitable for farmland sprinkler and drip irrigation systems, corrosion-resistant and easy to install;

Industrial fluid transportation: especially suitable for chemical plants, sewage treatment plants and other occasions that require corrosion-resistant pipeline systems;

Electric power protection sleeve: used for wire threading protection of wires and cables, with good flame retardant and insulation properties.

Although UPVC pipe fittings have many advantages, the following points should still be noted during use:

Avoid long-term use in high temperature environments, as their temperature resistance is limited;

Special glue should be used for bonding during installation to ensure that the interface is firm;

Products with added UV stabilizers should be selected in direct sunlight environments to extend service life;

The effects of thermal expansion and contraction should be considered when designing the pipeline system, and expansion joints should be set reasonably.

With the promotion of green buildings, energy-saving and environmental protection concepts, UPVC pipe fittings are gradually replacing traditional metal pipeline systems with their excellent performance and environmental protection characteristics, becoming the mainstream choice in modern pipeline engineering. In the future, with the advancement of technology and the research and development of new modified materials, UPVC pipe fittings will play an important role in more high-end fields.