1. Introduction to UPVC Pipe Fittings

1.1 What is UPVC?

UPVC, or Unplasticized Polyvinyl Chloride, is a rigid form of PVC (Polyvinyl Chloride) that does not contain plasticizers, making it stronger and more durable than its flexible counterpart. UPVC is widely used in the construction and plumbing industries due to its excellent mechanical and chemical properties. It is resistant to corrosion, chemicals, and weathering, which makes it ideal for pipe and fitting applications.

Unlike traditional PVC, UPVC maintains its rigidity even under stress, ensuring long-term reliability in piping systems. It is commonly used for water supply, drainage, irrigation, and various industrial applications.

1.2 Why Use UPVC Pipe Fittings?

UPVC pipe fittings serve as the connectors that join UPVC pipes together, allowing for changes in direction, branching, or adapting different pipe sizes. They play a crucial role in the integrity and performance of a piping system.

Reasons to choose UPVC fittings include:

Durability: UPVC fittings resist corrosion, scaling, and chemical attack, ensuring longevity.

Lightweight: Easier to handle and install compared to metal fittings.

Cost-effective: Lower material and installation costs.

Ease of Installation: Compatible with solvent welding, threaded, and flanged connection methods.

Low Maintenance: Minimal upkeep required after installation.

Environmentally Friendly: UPVC is recyclable and has a lower carbon footprint than many metals.

1.3 Advantages and Disadvantages of UPVC

Advantages:

Excellent resistance to corrosion and chemicals.

Long service life (typically 50 years or more).

Non-toxic and safe for potable water systems.

Good thermal insulation properties.

Smooth interior surface reduces friction losses.

Disadvantages:

Lower temperature tolerance compared to metals and CPVC (usually up to 60°C).

Brittle at very low temperatures, which can cause cracking.

Susceptible to UV degradation if not properly protected.

Limited pressure handling compared to metal alternatives in some cases.

2. Types of UPVC Pipe Fittings

UPVC pipe fittings come in a variety of shapes and designs to accommodate different piping system requirements. Each fitting type serves a specific purpose, enabling smooth transitions, changes in direction, or connections between pipes of varying sizes. Below are some of the most common UPVC fittings used in plumbing and construction projects:

2.1 Couplings

Couplings are straight fittings used to connect two pipes of the same diameter in a straight line. They are essential for extending pipe runs and repairing broken pipes.

2.2 Elbows (45-degree and 90-degree)

Elbows allow for changes in the direction of the piping system. The most common are 90-degree and 45-degree elbows, used to create right-angle bends or gentle curves, respectively.

2.3 Tees

Tee fittings enable the branching of one pipe into two or the merging of two pipes into one. They are shaped like the letter “T” and are widely used for distributing or collecting fluids.

2.4 Reducers

Reducers connect pipes of different diameters, allowing for size transitions within the piping system. They are essential when adapting large pipes to smaller ones without compromising flow.

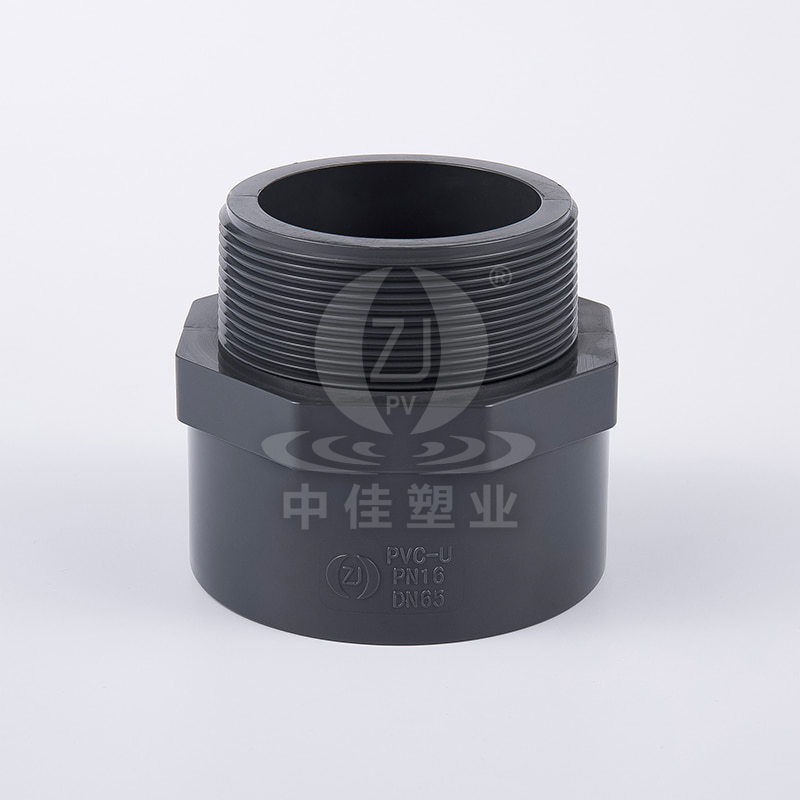

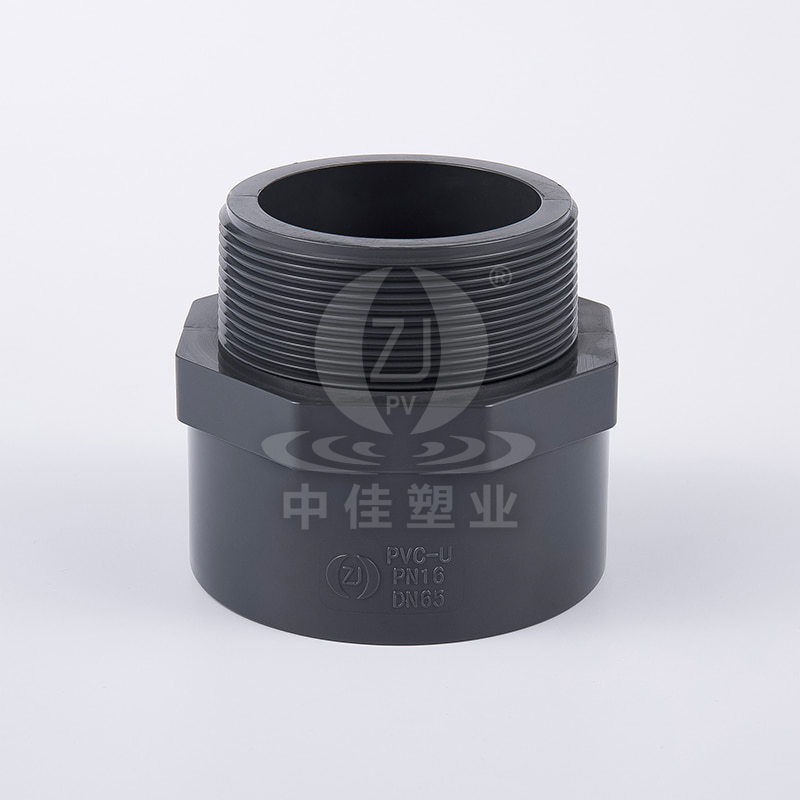

2.5 Adapters

Adapters connect pipes to components with different connection types, such as converting from a UPVC socket to a threaded metal fitting or valve.

2.6 Unions

Unions allow for easy disconnection and reconnection of pipes without cutting. They are especially useful in maintenance and repair scenarios.

2.7 Caps

Caps seal the end of a pipe, preventing flow or contamination. They are used to close off unused pipe sections safely.

2.8 Plugs

Plugs are inserted into the end of a pipe fitting or pipe to block flow, similar to caps, but often used internally within fittings.

2.9 Bushings

Bushings reduce the size of the pipe fitting opening, enabling connection to smaller pipes or components.

2.10 Other Specialized Fittings (Crosses, Wyes, etc.)

Crosses allow four-way connections.

Wyes create Y-shaped branches for smoother flow in drainage systems.

Lateral Tees combine features of tees and wyes for specific directional flow.

Barbed Fittings connect flexible hoses to rigid pipes.

Compression and Flare Fittings provide secure, leak-proof joints in specialized applications.

3. UPVC Pipe Fitting Sizes and Dimensions

Choosing the right size of UPVC pipe fittings is critical to ensure a secure connection and efficient flow within a piping system. Understanding the standard sizes and dimensions helps in selecting the correct fittings for your project.

3.1 Standard UPVC Pipe Sizes

UPVC pipes and fittings come in a variety of standard diameters, commonly measured in either inches or millimeters. Typical nominal diameters range from ½ inch (15mm) up to 12 inches (300mm) or more, depending on the application.

The most popular sizes for residential and commercial plumbing generally include:

½ inch (15mm)

¾ inch (20mm)

1 inch (25mm)

1½ inch (40mm)

2 inch (50mm)

3 inch (75mm)

4 inch (100mm)

Larger diameters are typically used in industrial or municipal water supply and drainage systems.

3.2 Understanding Schedules (Schedule 40, Schedule 80)

The term "schedule" refers to the wall thickness of the pipe and fitting:

Schedule 40 (SCH 40): Standard thickness used for general plumbing and water supply. Offers a balance between strength and cost.

Schedule 80 (SCH 80): Thicker walls providing higher pressure tolerance and durability. Suitable for high-pressure applications.

Choosing the appropriate schedule depends on factors like pressure requirements, installation environment, and mechanical stresses.

3.3 Measuring UPVC Pipe Fittings

When selecting fittings, it’s essential to consider:

Nominal Pipe Size (NPS): The approximate inside diameter.

Outside Diameter (OD): Important for socket or slip fittings.

Length and Depth: The insertion depth of pipe into fittings for proper bonding and sealing.

Manufacturers typically provide detailed dimension charts to ensure compatibility and proper fit.

4. Applications of UPVC Pipe Fittings

UPVC pipe fittings are versatile components used across various sectors due to their durability, chemical resistance, and ease of installation. Here are the primary applications where UPVC fittings excel:

4.1 Plumbing Systems

UPVC fittings are extensively used in residential and commercial plumbing systems for cold water distribution, drainage, and venting. Their corrosion resistance and smooth internal surface reduce the risk of leaks and blockages.

4.2 Irrigation

In agricultural and landscape irrigation, UPVC fittings connect pipes that distribute water efficiently over large areas. Their lightweight nature and chemical resistance to fertilizers and pesticides make them ideal for irrigation networks.

4.3 Industrial Applications

UPVC fittings are used in various industries to handle fluids, including chemical processing plants, wastewater treatment, and manufacturing. They resist corrosion from acids, alkalis, and other chemicals, making them suitable for harsh environments.

4.4 Drainage and Waste

UPVC fittings are common in drainage and waste management systems, such as soil stacks, sewer lines, and stormwater drainage. Their strength and resistance to bio-corrosion ensure reliable performance.

4.5 Chemical Handling

Due to their chemical inertness, UPVC fittings are preferred in pipelines carrying corrosive substances like acids and salts. This extends the lifespan of piping systems in chemical industries and laboratories.

5. Installation Techniques for UPVC Pipe Fittings

Proper installation is crucial for ensuring leak-proof and durable joints in UPVC piping systems. Several connection methods are used depending on the application, pipe size, and fitting type.

5.1 Solvent Welding

Solvent welding (also called solvent cementing) is the most common method for joining UPVC pipes and fittings. It involves applying a solvent-based adhesive that temporarily softens the surfaces of the pipe and fitting, which then fuse as the solvent evaporates.

Steps for Solvent Welding:

Clean the pipe and fitting ends to remove dirt and grease.

Apply primer (if required) to both surfaces.

Brush solvent cement evenly onto the pipe and fitting.

Immediately join the parts with a slight twisting motion.

Hold firmly for a few seconds to allow the bond to set.

Allow adequate curing time before pressure testing.

5.2 Threaded Connections

Threaded fittings screw onto pipes with matching threads. This method allows for easy assembly and disassembly, suitable for smaller diameter pipes and fittings.

Use appropriate thread sealant tape or compound to prevent leaks.

Ensure threads are clean and undamaged before assembly.

Do not overtighten to avoid cracking UPVC fittings.

5.3 Flanged Connections

Flanged fittings provide a mechanical connection through bolted flanges. These are typically used in larger diameter pipes or where frequent disassembly is needed.

Align flange faces and insert a suitable gasket.

Tighten bolts in a crisscross pattern to ensure even pressure.

Check for leaks during pressure testing.

5.4 Step-by-step Installation Guide

Measure and Cut: Measure pipe lengths accurately and cut using a fine-toothed saw or pipe cutter.

Deburr and Clean: Remove burrs and clean pipe ends thoroughly.

Dry Fit: Assemble parts without adhesive to ensure correct fit and alignment.

Apply Solvent Cement: Follow solvent welding steps carefully.

Assemble and Secure: Join fittings and hold in place until set.

Cure: Allow recommended curing time before pressure testing.

Pressure Test: Verify joints are leak-free before putting the system into service.

5.5 Best Practices for Leak-Proof Joints

Always use compatible solvent cement recommended for UPVC.

Avoid excessive cement application to prevent weakening the joint.

Work in well-ventilated areas to ensure safety and solvent evaporation.

Use correct tools and PPE such as gloves and goggles.

Follow manufacturer guidelines and standards for installation.

6. Comparing UPVC with Other Pipe Materials

When selecting piping materials, understanding how UPVC compares to alternatives like PVC, CPVC, ABS, and metal pipes helps determine the best choice for your application.

6.1 UPVC vs. PVC

Composition: UPVC is unplasticized PVC, meaning it lacks plasticizers found in flexible PVC.

Rigidity: UPVC is rigid and strong, suitable for structural piping; PVC can be flexible.

Applications: UPVC is commonly used in plumbing and drainage; flexible PVC is used for electrical conduit and hoses.

Chemical Resistance: Both offer good chemical resistance, but UPVC has higher mechanical strength.

6.2 UPVC vs. CPVC

Temperature Tolerance: CPVC can handle higher temperatures (up to ~90-100°C) than UPVC (~60°C).

Cost: CPVC is generally more expensive.

Applications: CPVC is favored for hot water lines; UPVC is mainly for cold water and drainage.

Chemical Resistance: CPVC has better resistance to higher temperature chemicals.

6.3 UPVC vs. ABS

Material Type: ABS (Acrylonitrile Butadiene Styrene) is another rigid plastic used in plumbing.

Impact Resistance: ABS is more impact resistant than UPVC.

Chemical Resistance: UPVC performs better against acids and alkalis.

Applications: ABS is popular in drainage systems; UPVC is more versatile across water supply and industrial uses.

6.4 UPVC vs. Metal Pipes

Corrosion Resistance: UPVC does not corrode, unlike metal pipes.

Weight: UPVC is lighter and easier to install.

Cost: UPVC generally costs less upfront and requires less maintenance.

Strength: Metal pipes have higher pressure and temperature ratings.

Longevity: UPVC resists chemical degradation but may be less durable mechanically in certain harsh environments.

7. Common Problems and Solutions with UPVC Pipe Fittings

Despite their durability and versatility, UPVC pipe fittings can encounter certain issues during installation or use. Understanding these common problems and their solutions can help maintain the integrity of your piping system.

7.1 Leaks

Causes:

Improper solvent welding or insufficient curing time.

Damaged or dirty pipe and fitting surfaces.

Misaligned joints or incorrect fitting sizes.

Cracks or defects in the fittings.

Solutions:

Ensure proper cleaning and priming before solvent welding.

Allow adequate curing time as per manufacturer recommendations.

Check alignment carefully during assembly.

Replace damaged fittings promptly.

Use thread sealants for threaded connections.

7.2 Cracking

Causes:

Exposure to UV radiation without protection.

Mechanical stress or impact.

Low temperatures causing brittleness.

Chemical exposure beyond UPVC resistance limits.

Solutions:

Use UV-resistant coatings or paint if exposed outdoors.

Provide mechanical protection or padding.

Avoid installation in extreme cold without insulation.

Confirm chemical compatibility before use.

7.3 Joint Failures

Causes:

Poor welding technique.

Thermal expansion and contraction stress.

Excessive vibration or movement.

Using incompatible fittings or adhesives.

Solutions:

Train installers in proper welding procedures.

Incorporate expansion joints or loops where necessary.

Secure pipes to minimize vibration.

Use fittings and adhesives recommended by manufacturers.

7.4 Preventing Common Issues

Conduct thorough inspections before and after installation.

Follow manufacturer guidelines strictly.

Store fittings properly to avoid damage before use.

Plan piping layout to minimize stress points.

Schedule routine maintenance checks.

8. Maintenance and Care of UPVC Pipe Fittings

Proper maintenance extends the lifespan and performance of UPVC pipe fittings, ensuring the reliability of your piping system over time.

8.1 Regular Inspections

Perform routine visual checks for signs of leaks, cracks, or discoloration.

Inspect joints and connections for looseness or wear.

Check for any signs of chemical degradation or physical damage.

Monitor pressure and flow to detect anomalies indicating hidden issues.

8.2 Cleaning and Protection

Clean fittings periodically to remove dirt, debris, or chemical residues using mild detergents.

Avoid abrasive cleaners or solvents that can damage UPVC material.

Protect outdoor fittings from UV exposure by applying suitable UV-resistant coatings or paints.

Ensure proper insulation in cold environments to prevent brittleness.

8.3 Extending the Lifespan of UPVC Fittings

Use fittings within their recommended temperature and pressure ratings.

Avoid mechanical stresses by properly supporting pipes and fittings.

Replace worn or damaged components promptly to prevent system failure.

Follow manufacturer guidelines for storage and handling.

Train maintenance personnel in proper inspection and care techniques.

9. Cost Considerations for UPVC Pipe Fittings

Understanding the cost factors involved with UPVC pipe fittings can help you make informed decisions balancing budget and performance.

9.1 Initial Costs

UPVC fittings are generally more affordable than metal alternatives like copper or stainless steel.

The material cost combined with ease of installation can significantly reduce labor expenses.

Bulk purchasing and standardized sizes often bring further cost savings.

9.2 Long-Term Savings

Low maintenance requirements mean fewer repairs and replacements.

Resistance to corrosion and chemical damage extends the service life.

Reduced downtime during installation and repairs increases operational efficiency.

Energy savings from UPVC’s insulating properties may be realized in some applications.

10. Safety Precautions When Working with UPVC Pipe Fittings

Ensuring safety during the handling, installation, and maintenance of UPVC pipe fittings protects workers and maintains system integrity.

10.1 Handling UPVC

Handle fittings carefully to avoid cracks or damage.

Store fittings in a cool, shaded area away from direct sunlight to prevent UV degradation.

Avoid dropping or subjecting fittings to heavy impact.

10.2 Using Solvents and Adhesives Safely

Work in well-ventilated areas to avoid inhaling fumes from solvent cements and primers.

Use gloves and eye protection when handling solvents and adhesives.

Keep solvents away from heat sources or open flames due to flammability.

Follow manufacturer instructions and safety data sheets closely.

10.3 Protective Gear

Wear gloves to protect skin from chemical exposure.

Use safety goggles to guard against splashes during solvent welding.

Employ respiratory protection if working in poorly ventilated spaces.

Use appropriate clothing to avoid contact with solvents and dust.

11. Conclusion

11.1 Recap of UPVC Pipe Fitting Benefits

UPVC pipe fittings offer a durable, cost-effective, and versatile solution for a wide range of plumbing, irrigation, industrial, and drainage applications. Their resistance to corrosion, chemical stability, and ease of installation make them a preferred choice in many projects. By understanding the types, sizes, applications, and installation techniques, users can maximize the performance and longevity of UPVC piping systems.

11.2 Future Trends in UPVC Technology

Advancements in UPVC materials and manufacturing processes continue to enhance the strength, flexibility, and environmental friendliness of pipe fittings. Innovations like UV-stabilized coatings, improved solvent cements, and integration with smart monitoring systems are paving the way for more sustainable and efficient piping solutions in the future.