How Do uPVC Tee Fittings Contribute to Easy Installation and Maintenance in Piping Systems?

In modern plumbing and industrial piping systems, efficiency, durability, and ease of maintenance are essential for ensuring smooth operation and long-term reliability. Among the many components that make up a piping network, uPVC (unplasticized polyvinyl chloride) tee fittings stand out as versatile and practical solutions for branching pipelines. Their unique material properties, design, and compatibility with various piping systems make them widely used in residential, commercial, and industrial applications.

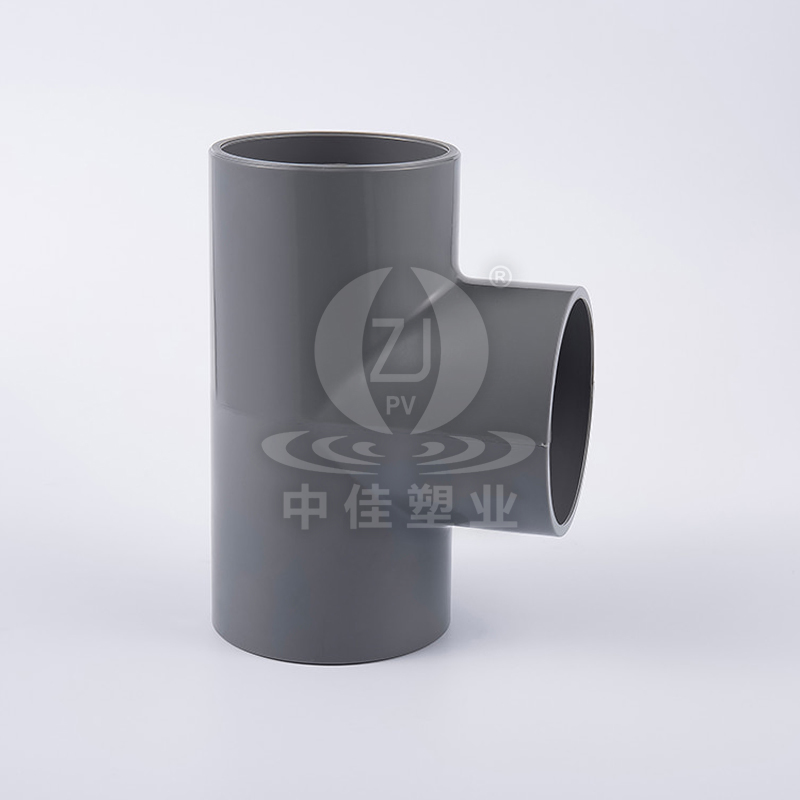

1. Overview of uPVC Tee Fittings

A tee fitting is a T-shaped component that allows fluid to flow through a main pipeline while branching into a secondary line at a 90-degree angle. Tee fittings are commonly used to:

- Distribute water, chemicals, or other fluids to different areas.

- Connect pipelines of the same or varying diameters.

- Facilitate maintenance by allowing branch lines to be isolated or redirected.

The uPVC material provides rigidity, chemical resistance, and corrosion resistance, making these fittings suitable for potable water systems, irrigation, chemical processing, and sewage networks. Unlike metal fittings, uPVC tees do not corrode, rust, or scale over time, significantly simplifying maintenance.

2. Lightweight Design for Simplified Handling

One of the primary reasons uPVC tee fittings contribute to easy installation is their lightweight nature.

- Ease of Handling: uPVC is significantly lighter than traditional metal materials like steel or copper. This reduces physical strain during installation, allowing a single worker to handle larger fittings without heavy lifting equipment.

- Simplified Transportation: Lightweight fittings are easier to transport to construction sites, particularly in large-scale plumbing projects or remote areas.

- Faster Installation: Because installers can quickly maneuver and position the fittings, the overall installation time is reduced, improving project efficiency.

In contrast, metal tee fittings require careful handling, lifting tools, and additional labor, which can increase installation complexity and time.

3. Easy Cutting and Joining

Another factor contributing to easy installation is the workability of uPVC material.

- Simple Cutting: Pipes and branch lines can be easily cut using basic saws or pipe cutters without specialized tools. This allows for quick adjustments on-site, accommodating precise measurements and unexpected changes.

- Solvent Welding: uPVC tee fittings are typically joined using solvent cement, which chemically fuses the pipe and fitting into a single, leak-proof unit. This eliminates the need for threading, welding, or complex flange connections required by metal systems.

- Consistent Connections: Solvent-welded joints provide uniform strength and leak-free performance, reducing the risk of installation errors and future maintenance issues.

The combination of cut-to-fit flexibility and simple bonding ensures that installation is fast, efficient, and reliable, even for complex piping networks.

4. Corrosion and Chemical Resistance

uPVC tee fittings are inherently resistant to corrosion, chemical degradation, and scaling, which directly impacts maintenance requirements.

- No Rust or Corrosion: Unlike steel or iron fittings, uPVC does not oxidize, preventing pipe blockages and leaks caused by corrosion.

- Chemical Compatibility: uPVC is resistant to acids, alkalis, salts, and other chemical agents commonly found in industrial fluids, water treatment, or irrigation systems.

- Extended Lifespan: The durability of uPVC reduces the need for frequent replacement or repairs, making long-term maintenance easier and less costly.

This chemical and corrosion resistance ensures that installers and maintenance teams spend less time inspecting, cleaning, or replacing fittings, simplifying overall system upkeep.

5. Leak-Proof Design

Leak prevention is a critical factor in piping system reliability. uPVC tee fittings are designed to provide tight, secure connections, which simplifies maintenance in several ways:

- Solvent-Welded Joints: The chemical bonding process creates a homogeneous joint that eliminates gaps or loose fittings.

- Precision Manufacturing: uPVC fittings are molded with high dimensional accuracy, ensuring proper alignment with pipes and reducing the chance of leaks.

- Smooth Inner Surface: The smooth interior reduces friction and prevents sediment buildup, which can otherwise cause blockages and require frequent cleaning.

Reliable, leak-proof connections reduce the need for regular inspections, re-tightening, or seal replacement, significantly lowering maintenance efforts.

6. Versatility in Pipeline Systems

uPVC tee fittings can be used in a variety of pipeline configurations, contributing to flexibility and ease of installation:

- Branching Lines: The tee allows for efficient fluid distribution, minimizing the need for additional fittings and complex routing.

- Integration with Existing Systems: uPVC tees are compatible with other uPVC pipes and fittings, as well as adapters for metal or CPVC systems, allowing easy integration during repairs or retrofitting.

- Customizable Flow Paths: Tee fittings can be installed in horizontal, vertical, or angled configurations, adapting to space constraints and system requirements.

This versatility simplifies both initial installation and future modifications, reducing the need for complicated redesigns.

7. Minimal Tooling Requirements

Installing uPVC tee fittings requires minimal specialized equipment, which contributes to efficiency and cost-effectiveness:

- Basic Tools: Standard pipe cutters, deburring tools, and solvent cement are typically sufficient for installation.

- No Welding or Threading: Unlike metal fittings that require skilled labor for welding or threading, uPVC fittings are accessible to general plumbers or maintenance personnel.

- Quick On-Site Adjustments: Minor adjustments and alignment corrections can be performed quickly without specialized machinery.

The simplicity of installation reduces labor costs and project timelines while ensuring consistent results.

8. Low Maintenance Over the Lifecycle

uPVC tee fittings contribute to long-term ease of maintenance due to several inherent properties:

- Durability: uPVC’s resistance to UV, chemicals, and corrosion ensures that fittings maintain structural integrity over decades.

- Non-Scaling Surface: Smooth inner surfaces prevent mineral deposits, scaling, and clogging, which reduces cleaning and pipe flushing requirements.

- Ease of Replacement: In the rare event of damage, uPVC tees can be quickly cut out and replaced with minimal disruption to the system.

These characteristics make uPVC tee fittings ideal for systems where ongoing maintenance access may be limited, such as underground pipelines or irrigation networks.

9. Cost-Effectiveness

Ease of installation and maintenance translates into significant cost savings:

- Reduced Labor Costs: Lightweight, easy-to-handle fittings require fewer workers and less time for installation.

- Lower Maintenance Costs: Durable, corrosion-resistant materials reduce repair frequency and spare parts expenses.

- System Longevity: The reliability of uPVC fittings extends pipeline lifespan, decreasing overall lifecycle costs.

Overall, the combination of reduced installation complexity and low maintenance requirements makes uPVC tee fittings a highly cost-effective choice for both small-scale and large-scale piping systems.

10. Conclusion

uPVC tee fittings contribute significantly to easy installation and maintenance in piping systems through a combination of:

- Lightweight design, simplifying handling and installation.

- Easy cutting and solvent welding, enabling fast, secure connections.

- Corrosion and chemical resistance, reducing long-term maintenance needs.

- Leak-proof, precision design, ensuring reliable performance.

- Versatility, allowing integration into diverse pipeline layouts.

- Minimal tooling requirements, reducing labor and complexity.

- Durability and low maintenance, extending system lifespan and reducing costs.

- Cost-effectiveness, combining lower installation, repair, and replacement expenses.

These advantages make uPVC tee fittings a preferred choice for residential, commercial, and industrial piping systems, particularly in applications where reliability, efficiency, and long-term maintenance simplicity are essential. By selecting high-quality uPVC tee fittings, engineers and maintenance personnel can ensure that piping networks operate smoothly, safely, and economically over their service life.